|

Design and Analysis of Flows in Energy Systems |

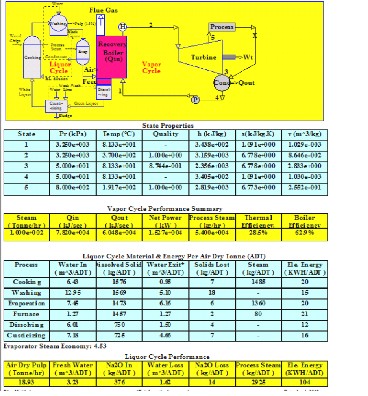

Integrated Liquor and Vapor Cycle Analysis of Chemical Recovery Process

|

| Chemical recovery is an important part of the chemical pulping process with a potential to generate energy by burning all non-cellulose wood compounds. Hence, energy conservation in both liquor and vapor cycle needs an integrated approach. Any variation in parameters of the pulping process can influence both chemical recovery as well as energy generation. Therefore, it is necessary to evaluate material balance primarily water and total solids at every stage of liquor cycle in order to identify all potential areas and to boost conservation efforts. Furthermore, combustion heat availability and thermal efficiency of the vapor cycle is direct reflection of the liquor cycle performance. |

| The schematic of both liquor and vapor cycle is shown in the model space. Graphical user interface is provided with in the model space where it will respond to all mouse clicks in order to edit, append, and modify different system components. Executive summary of both liquor, and vapor cycle as shown in description space. For liquor cycle, stage wise material balance and energy consumption per ton of air-dry pulp (ADP) is provided for better comprehension. This normalized data helps compare and monitor all processes irrespective of the individual plant size and helps identify all areas of energy loss. For vapor cycle, over all thermal and boiler efficiency is analyzed that helps set realistic goal for energy conservation measures. |